Industrial water purifier or industrial water desalination, known as RO or reverse osmosis, is an advanced method and desalination water production technology that is useful for commercial and commercial exports in modern and developing countries. To produce fresh drinking water, the U.S. Navy first used industrial-scale salt water using reverse osmosis technology to provide fresh drinking water for its forces.

In many countries, reverse osmosis or RO processes are used to purify water for different purposes, such as mineral water machine or water treatment plant. There are many suppliers and factories around the world that offer a wide range of machines for sale.

Water Commercial export

Today, as water resources are depleted, groundwater levels are salted in various areas, and their use requires water care and purifying. Just as water treatment of plants is proposed as a selective process in certain countries and is even used for commercial use by developing the prerequisites for new water sources.

One of the main motives behind the filtered drinking water is drinking water. In different areas, with the total and type of salt water, use a water purification device or a domestic water purifier, or for a further expansion, industrial water purifier. No doubt, even in general, drinking water in the city in order to meet its standard quality is done the same way. The filtered water is used in various functions along drinking water. agricultural trade, livestock breeding, poultry development, agriculture etc. all need fresh water for their industry.

In many countries, agricultural goals have taken into account a large part of groundwater resources. With the increase in underground salts, the well’s water should be purified. This is especially important for the agricultural sector in Greenhouse. In greenhouse agriculture, all the components expected by plants, such as water, light, temperature, soil supplements, etc, are carefully considered. Controlling these factors increases efficiency and productivity. Cattle must also be provided with drinking water. Cattle breeding, poultry farming, fish reproduction and various marine animals must move towards safe water for their activities.

The water standard used in these industries is the actual standard of drinking water. Consumption of unsafe water causes illness of organisms. Water purification of fish-simulation lakes is very sensitive. Various efforts, such as food, medicine, welfare and reconstruction organizations, likewise have an unprecedented prerequisite for pure water. Water is directly used in food production. The use of treated water extends the idea of beverage and other beverage products.

Water purifier export

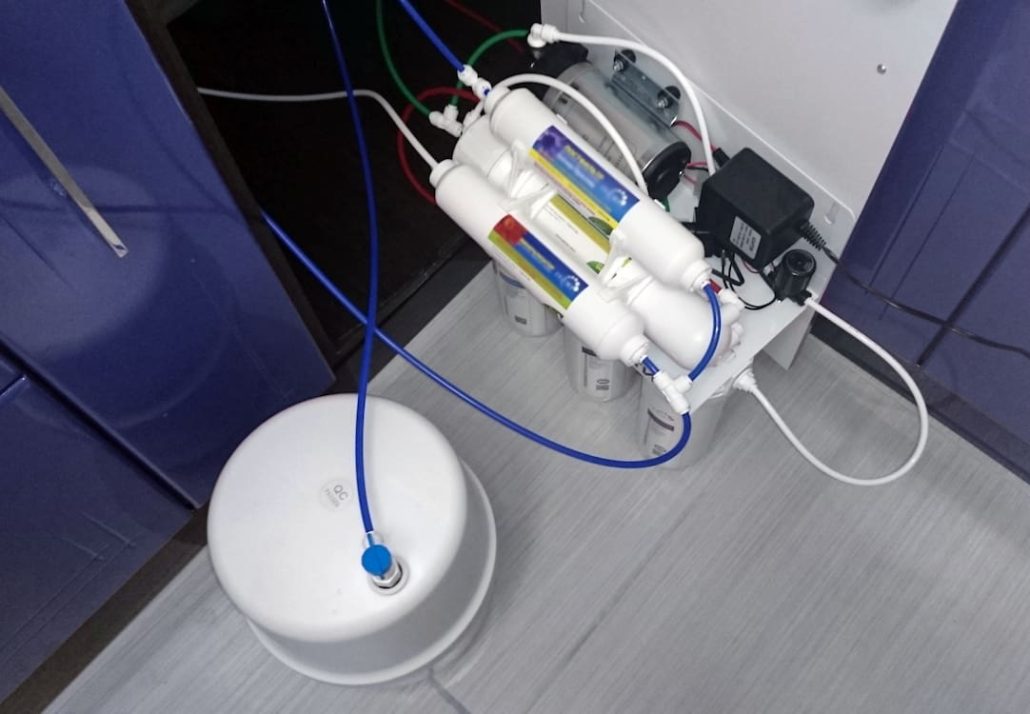

Different water sources can include various impurities. It is very important to carefully examine how completely different deviations such as suspended solids, particles and salts, considerable metals and ions, etc. should be considered in designing a reverse osmosis (RO) water sterilizer groups and arrangement of opposing osmosis structure. Water treatment machine has these parts: water pretreatment surface Suspended solid particles, considerable metals and many gases are the basic part of the pollution plan of various water sources and its care in relation to the purification, as well as hitting the latest sterile water idea, in addition, it expands the future and introduces reverse osmosis filter channels. These filters are placed in pre-treatment periods, the purification of the switching water by a variety of sand filter channels, sediment filters, and water-free carbon filter channels.

high pressure pump In the pre-treatment period of the current water treatment, the particles and salts are not released from the water, and it is necessary to increase the pressure more than osmotic pressure to remove them through the opposing osmosis process. This pressure is in reverse osmosis (RO) water purifier for the parts offered by floor pumps and occasional by the chamber pumps. Therefore, this means a bit for direct selection according to flow rate, how much elimination and ideal quality for the result of water conditioning structures.

Latest Water Purification and Ion Removal With Reverse Osmosis Filter Channels (RO) High pressure leads to improve the process despite water flow through relatively permeable Osmotic filters from the higher osmotic pressure to lower osmotic pressure and the reverse osmosis process is done similarly and continuously. Reverse osmosis (RO) is selected by completing a guidance program point to reach the greatest possible number of particles and salt disposal, and their proper design helps increase water recovery and reduce the number of scams.

Disinfectant Various sources of water, especially surface water and seawater, can include many organisms and small diseases. In the arrangement and improvement of reverse osmosis water structure (RO), the tiny creatures and diseases are killed or eliminated by the most reliable and modern water purification technology, as UV Filter (UV), with the aim that sterile water is pure and healthy in the water treatment system.

Commercial Water Purifier

Several countries on the planet produce machines, systems, and frameworks for water supply in global commercial markets. The market for this industrial and household product is exceptionally prosperous in light of the accompanying needs: In Demand for planning and creation of drinking water from saltwater (beverage goals).

Industrial Water Purification Machines For Supplying and Creating Water Needed For Rapid Growth of Animals and Poultry Industrial Water Cleaning Machine For Providing And Creating Water Suitable For Garden Use And Greenhouse Industrial Water Treatment System and Plant For Supply and Creation of Water Processed and Purified For Drugs and Beauty Care Products In the list and create cycle water for petrochemical, steel, material, papermaking, paint, etc.

Development of desalination plants and combined cycle In order to supply and provide water to steam boilers, refrigeration frameworks and intensity converters.

Commercial Water export

The biggest change in innovation in the 1990s in the United States was providing computer innovation to modern water treatment plants, which began to engage the PLC and PC innovation for control. Therefore, he considered modern wastewater as an important part of creating interaction, taking into account the special costs of ecological insurance. The “Zero Water Waste” movement in the United States started to become the main point of the organization in water treatment.

Advances made during the 1990s were used in the full use of limited assets (space, climate and climate) in this period, minimization, hybrid substitution strategies for the removal or reduction of despairing destructive materials, industrial advances, depletion supplements, and layer enhancements for UV.

Reuse of synthetic lesions in treatment is more important for organizations. As the 21st century enters, however the pace of industrial infrastructure development in the United States is 58%, the modern sewage volume will decrease from 62 billion gallons to 22.32 billion gallons per day through industrial waste recycling and reuse.