Fluid transfer up to a height of about 100 meters and more requires pumps that have a stronger pressure. Industrial water softeners also need these types of pumps for better and faster use. The size of the boiler feeding pumps requires a high pressure pump due to its high height. Is.

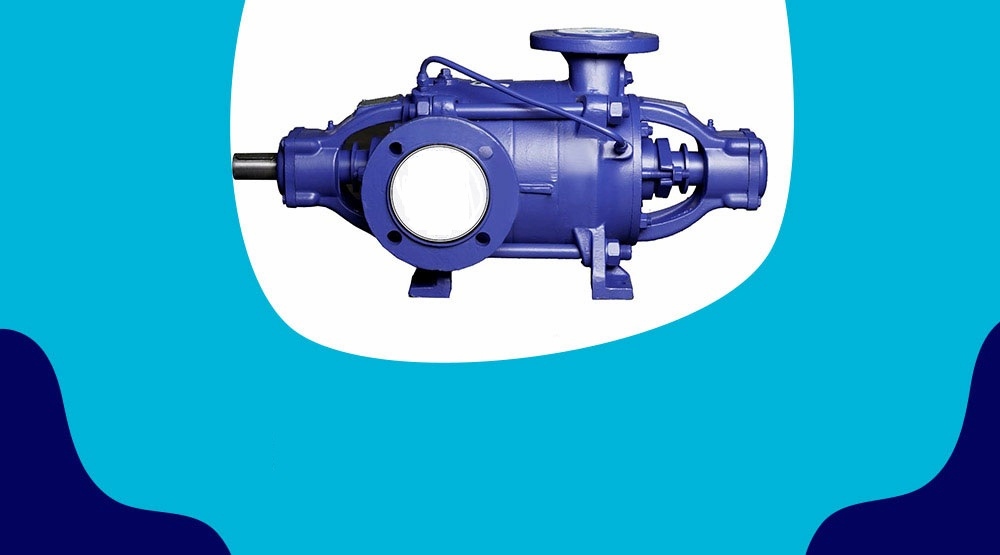

In fact, these pumps are multi-stage centrifuges that have many applications such as urban water supply, water pumping and drainage. The impeller diameter and higher engine speed, the number of impellers and the addition of floors in the pumps are among the most important features. High pressure pump supplies water.

The high-pressure pump is made of a fabric-shaped chamber, which consists of a suction chamber, a thrust chamber, and chambers with the number of floors of the high-pressure pump. Closing these floors with screws creates a connection between them. The suction chamber, on the left side of the pump, injects fluid pressure into the pump and then enters the impeller. The diffuser behind the impeller converts velocity into pressure. Although the diffuser is stationary, the impeller inside rotates.

The mechanical coiling on the left side of the propellers is also responsible for holding the shaft and thus preventing the destruction of the pump. Fluids of each class require suction to pass through the impeller to reach the pump. After entering, they are also removed from the trust tube. become

High pressure desalination pump

Industrial desalination is a device that purifies and sweetens a large amount of water. Its difference with the home water softener is the amount of water and its scale. Therefore, high pressure pumps are made for brackish water such as sea water to make it suitable for agriculture and animal husbandry.

According to the volume of devices and the space to be allocated to it, devices can be selected that are suitable for the intended environment, although these changes are not many, but they can be effective to achieve the goal.

Today, despite the drastic changes in the life of machines, water pollution is increasing strongly, so cleaning these pollutions requires devices that are also efficient. At this stage, a lot of pressure is needed, which is beyond the reach of desalinators, but high pressure pumps connected to them can be a suitable and optimal option. For the suitability of these pumps and their better performance, some factors should be considered. The effectiveness was greater.

The level of pollution of the incoming water, the quality of its output, and the water flow rate are among the factors that should be taken into consideration when purchasing these pumps.

To use these pumps, you should refer to the following sources:

Suction source: This source can be sea water, river water, etc.

Source of drift: filling the pool, irrigation of the field, water supply to the building, etc. are among the things that can be mentioned.

The amount of water supplied by these pumps is calculated in seconds and minutes, and the head is the water height from the beginning to the end of the source, which is calculated in meters in industrial projects.

If we want to briefly mention the types of high pressure pumps, we can mention the following:

Centrifugal pump: which has an outlet valve that does not open due to the pressure applied to the pump.

Combination pump: It is used for fluid flow and transfer, and its efficiency is that it connects a number of pumps together.

Piston pump: It is mandatory to close the pumping of this device.

Plunger pump: Although this device has a reliable valve, its pressure diameter is small.

Graphite pump: used for lower pressures and movements.

Reciprocating pump: which is used for high fluid pressure, although it should be kept in mind that the use of this pump causes a little energy loss.

High pressure industrial water pump

Today, due to the low water pressure in many homes and office and industrial buildings, especially during holidays and hot weather, the use of a high pressure water pump is considered an essential device for these places by providing this pump with the water collected in the tank with the help of its shortage. It comes in buildings.

The diameter of the impellers of pressure pumps is very influential in its hydraulic calculations, the rotor speed, the number of impellers, etc., are some important options in buying a good high pressure pump. It will result in poor performance. It is appropriate to use a lower engine speed for the longer life of these pumps so that the coiling bearings bear less pressure.

Note that the brands produced and the dimensions of the hydraulic pump types cause different price fluctuations, and according to the mentioned options, it is natural that they do not have the same prices.

Of course, the maintenance of this type of device requires care that makes its life longer and its efficiency higher. You can see these points below:

Turning on the pumps without water is very harmful for the device and puts a lot of pressure on it.

It is better to drain the water from the pump that you don’t use for a long time and fill the source with water after using it again.

The correct and principled installation of this device is one of the effective factors that make it more efficient. It is better to seek help from experts in this matter.

Pulling air by the pump will make the motor work continuously and this will damage your device.

Failure of the inner tube will reduce the air pressure of the pump and destroy the device.

It is essential to use an industrial switchboard for these pumps and there should be no carelessness in its installation.

Our company has taken a step towards helping you dear customers by providing all its modern and up-to-date service arrangements. We thank God that from now on we are your guide in this matter.

You can see the answers to your questions and demands by visiting our sales sites 24 hours a day. We hope our experts will guide you.